We Prioritize Security Above All Else

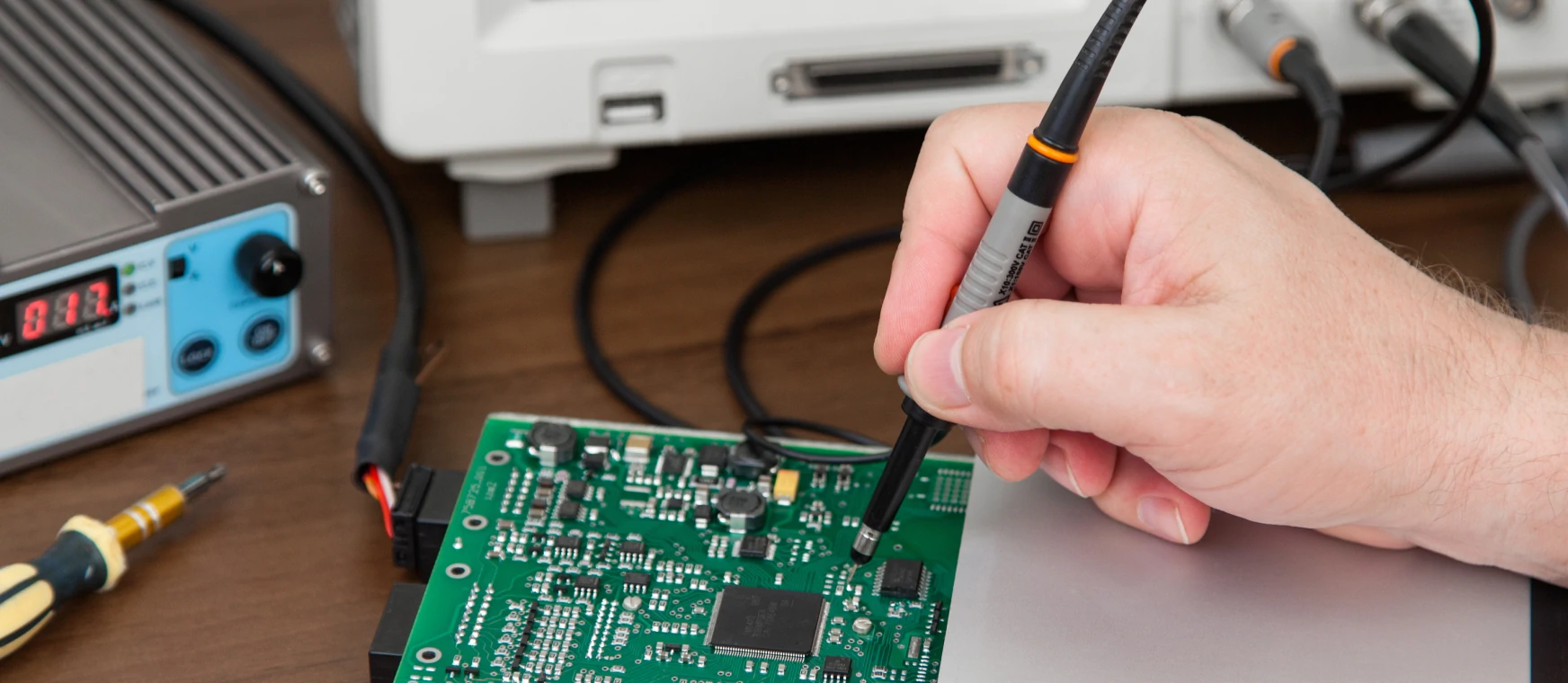

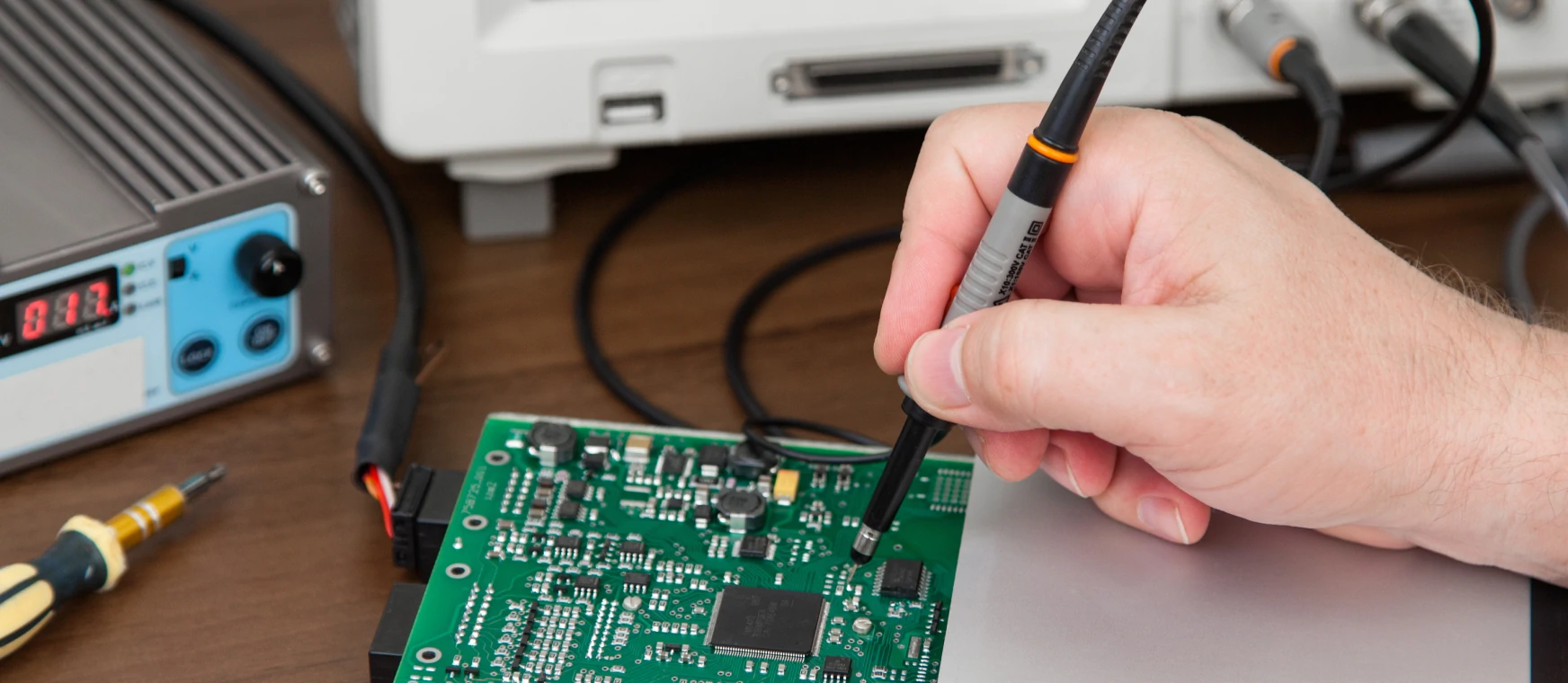

Analysis & Testing Laboratory

Our lab uses advanced analytical tools, turning findings into practical solutions for Industrial, Medical, Aerospace, and Defense sectors.

Factory Auditing

We have over 10 lean practitioners and certified auditors dedicated to investigating and ensuring supplier quality assurance at the component level.

Programming, Packaging and Logistics

We offer a wide range of services, including primary and secondary packaging, as well as thorough labeling and serialization solutions

Training and Development

We share our knowledge through seminars and workshops to benefit everyone involved.

Our Standard Testing Procedure at Intest

Intest's fully customizable functional testing services are prepared to meet a broad range of challenging requirements and timelines, encompassing full-unit and component-level testing.

- 01Visual Inspection of External Packaging

- 02Document Verification Check

- 03Detailed Visual Inspection

- 04Label Verification

- 05Digital Photography

- 06Requirement Verification

- 07Value-Added Testing

- 08Departs to Customer

- 09Approval

Value-Oriented Test Solutions

Intest is an independent electronic component testing entity, serving aerospace, defense, medical, automotive, and commercial industries. We fulfill all your testing requirements through our ISO 9001:2015 AS9120B certified partners.

Substandard And Counterfeit Mitigation

Detecting and preventing counterfeits early on significantly impacts the overall supply chain quality. Our inspections adhere to high-quality standards like AS6081, AS6171, AS5553, CCAP-101, and IDEA-1010.

- Inspecting Documents and Packaging01

- Conducting External Visual Checks02

- Utilizing X-ray Fluorescence (XRF)03

- Performing X-ray Analysis04

- Conducting Heated Solvent Tests05

- Carrying out Decapsulation and Die Analysis06

- Performing Electrical Tests07

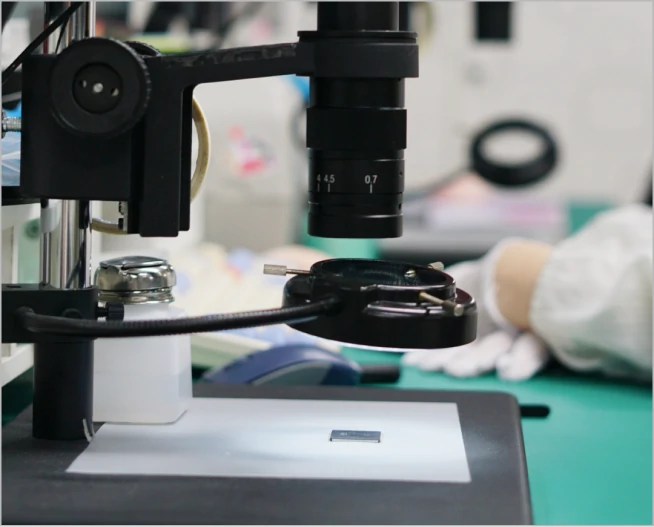

Failure Analysis

Unbiased failure analysis conducted by an independent testing laboratory empowers the production of superior-quality products.

- Scanning Electron Microscopy (SEM)01

- Energy Dispersive X-ray Spectrometry (EDX)02

- Scanning Accoustic Microscopy (SAM)03

- Cross-section (Microsection)04

- Parallel Lap05

- Hot Spot Test06

- Electrical Test07

Lifecycle And Reliability Testing

Lifecycle testing assesses a product's longevity by analyzing its performance under typical usage conditions. Reliability testing, on the other hand, exposes products to extreme conditions to simulate intensive use, surpassing normal operating requirements.

- Thermal Cycle01

- Thermal Shock02

- Burn-in03

- Drop Test04

- Vibration Test05

- Environmental Exposure (Temperature And Humidity)06

- Salt Spray Test07

- Electrical Overstress Testing08

- Mechanical Stress Testing09

Electrical Testing

We conduct tests at six varying levels, tailored to the device and customer's specifications. Our testing scope includes assessing component performance, speed, durability, and reliability, as well as detecting defects and faults.

- Curve Trace01

- Pin Verification Test02

- Functional Test (Primary)03

- DC Characteristics04

- AC Characteristics05

- Temperature Range Testing06