We Prioritize Security Above All Else

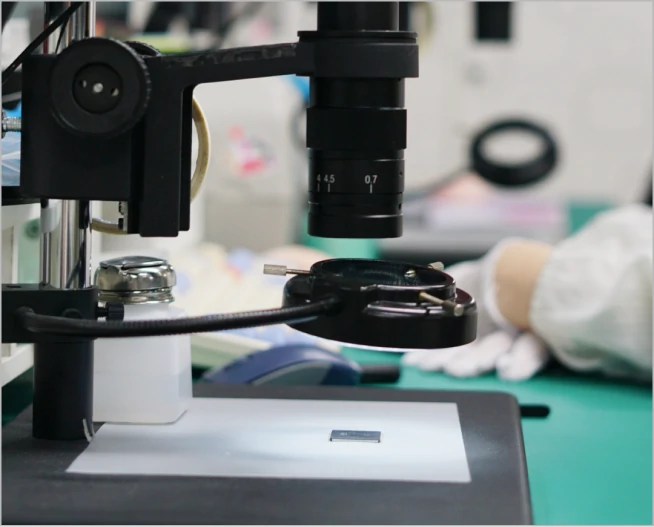

Analysis & Testing Laboratory

Our lab uses advanced analytical tools, turning findings into practical solutions for Industrial, Medical, Aerospace, and Defense sectors.

Factory Auditing

We have over 10 lean practitioners and certified auditors dedicated to investigating and ensuring supplier quality assurance at the component level.

Programming, Packaging and Logistics

We offer a wide range of services, including primary and secondary packaging, as well as thorough labeling and serialization solutions

Training and Development

We share our knowledge through seminars and workshops to benefit everyone involved.

Proven Optimization Programs

Drawing on our experience, Intest improves customer packaging solutions by assessing their supply chain. Through systematic analysis, we evaluate the existing packaging solution and suggest enhancements for cost savings without compromising product protection.

Our Services Include:

- Warehousing01

- Kitting02

- Drop-Shipment03

- Consolidation04

- Inspection05

- Packaging06

- International Shipping Documentation07

Complete Component Packaging Solutions:

Inadequately handled and packaged electronics can lead to significant damage to wires, assemblies, and the final products. Our aim is to ensure your goods are delivered to the production site in excellent condition and ready for use.

All packaging in our ESD controlled facilities adheres to JEDEC and EIA standards. Your product is stored in our climate-controlled warehouse and shipped later after proper MSL and ESD protective packaging.

- Tape and Reel01

- Transfer Carriers02

- Baking03

- Dry-pack04

- Re-boxing05

- Custom Labelling06

- Solderability Testing07

- External Visual Inspection08

Customized Programming Solutions

Our programming service simplifies and speeds up the testing process for electronics manufacturers. By outsourcing component programming to us, you save time and reduce production line complexity, leading to cost savings.

Choose us for your component programming needs, and enjoy lower costs, increased productivity, and a seamlessly integrated supply chain. Our fully automated systems can program, check co-planarity in 3D, mark, tape, and rewind your products at an impressive rate of up to 3,000 pieces per hour. With fast delivery, you can rest assured that your production deadlines will be met.

Enhancing Sustainability in Your Supply Chain